Air Compressor

A Comprehensive Guide to Compressed Air Lines on Ships: Everything You Need to Know

A Comprehensive Guide to Compressed Air Lines on Ships: Everything You Need to Know – On our website, you can find the best electronic products at advantageous prices.

✅ Choose free delivery to save even more

A Comprehensive Guide to Compressed Air Lines on Ships: Everything You Need to Know

Before purchasing our products, we recommend that you read the product description. If you have any doubts, do not hesitate to contact us. We will be happy to help you choose the most suitable product for your needs.

Contact us on Whatsapp: HERE

QUALITY GUARANTEE choose safety, savings, and professionalism, choose us. We offer top-notch assistance that will never leave you alone during the entire pre- and post-purchase phase. We offer high-quality products, smart and safe savings, do not rely on improvised sellers.

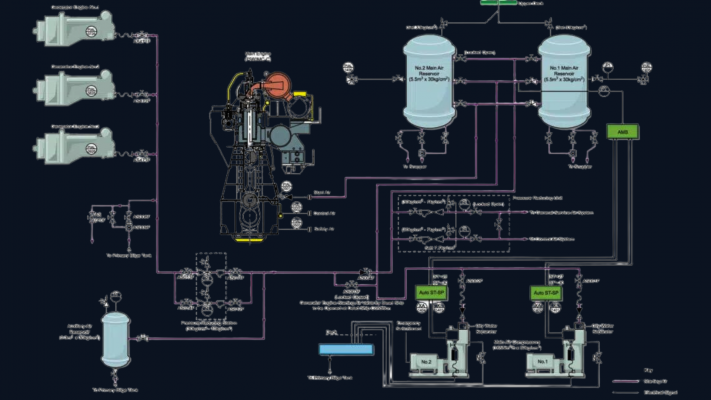

Ships rely on compressed air for a variety of important functions. One of the most critical uses of high-pressure air on ships is for starting the main engine. Typically, high-pressure air at a pressure of 30 bar is used for this purpose. However, this high-pressure air is usually reduced to lower working pressures through pressure reduction valves. The compressed air at reduced pressures of 7-8 bar is used as service air for many different applications.

There are numerous essential applications that rely on this lower-pressure air. For example, the starting of auxiliary engines and emergency generators, as well as charging freshwater and drinking water hydrophores. The compressed air is also utilized for blowing the fog horn, as spring air for exhaust valves of the main engine, and for dry washing of main engine turbochargers. Furthermore, it is used in sewage treatment plants for aerobic sewage breakdowns, soot blowing of boilers, and pneumatic pumps for oil transfers, amongst many other applications. Additionally, the service air is also used for cleaning, painting operations, chipping, and operating pneumatic tools, such as grinders and chisels.

Another crucial use of the 7-8 bar compressed air is as control air. This is a filtered branch of the service air that is free of any moisture and oil carry-over. The controlled air is used for pneumatic controllers, which are crucial for the operation of machinery onboard ships.

Overall, the air line is a crucial aspect of ship operations, and its importance cannot be overstated. In general, the complete pneumatic air line on a ship includes the main high-pressure airline, the service air line, and the control air line. Each of these lines serves a vital function in ensuring the safe and efficient operation of the ship’s machinery. This article aims to provide insight into the air line of a ship, including its important components and how it works. Understanding the air line is critical for anyone involved in the operation of ships or marine engineering.

Main Air Compressor

The heart of the air-line onboard a vessel is the main air compressor, responsible for compressing air by reducing its volume and increasing its pressure. With various types of air compressors available, including centrifugal compressors, rotary vane compressors, rotary screw compressors, and reciprocating air compressors, vessels can select the best option for their specific needs.

Most modern merchant vessels use multi-stage reciprocating air compressors that come equipped with intercoolers and aftercoolers, complete with automatic draining and unloading arrangements. These compressors have proven to be highly efficient and effective for vessel operations.

To measure the capacity of the main air compressor, the industry uses the term Free Air Delivery (FAD), which is expressed in cubic meters per hour. Free Air Delivery refers to the volume of air discharged by the compressor in one hour, taking into consideration that it would occupy the space if expanded down to atmospheric pressure and cooled to atmospheric temperature.

The pressurized air discharged by the main air compressor is stored in a main air bottle or reservoir, which has a maximum pressure of 30-32 bar. Depending on the capacity of each air compressor, the volume of air needed for starting the main engine, and the overall demand for air on the vessel, a ship may have two or three main air compressors.

In some cases, marine boilers and exhaust gas economizers on certain ships need air to be soot blown, requiring higher capacity air compressors to be employed at the design stage, based on the ship owners’ requirements.

According to SOLAS requirements, a ship’s main air compressors must be able to fill their air reservoirs from zero to maximum pressure (30bar) within one hour. This is a critical aspect of vessel safety, ensuring the air compressors can efficiently deliver the air supply needed for vessel operations in a timely manner.

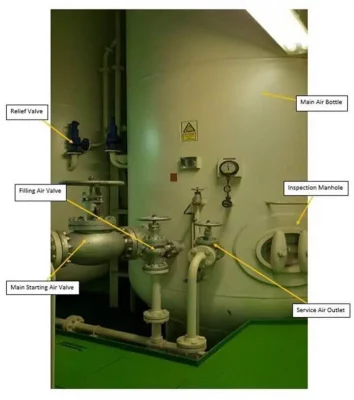

Main Air Reservoir

On board every ship, there is a crucial component that is responsible for ensuring the proper functioning of the engine. These components are called air reservoirs and each vessel is equipped with a set of two, which can either be of the vertical or horizontal type.

In order to guarantee that these air reservoirs function optimally, they are put through a rigorous hydraulic pressure testing process that ensures they can withstand up to 1.5 times their working pressure. This ensures that they can handle the high pressure demands of the ship’s engine without any issues.

Furthermore, in accordance with Solas regulations, each vessel must have air reservoirs with a total capacity that is sufficient enough to allow for a specific number of consecutive Main Engine starts. For reversible engines, the air reservoirs must be able to support at least 12 consecutive starts without needing to be refilled. Similarly, for non-reversible engines, the air reservoirs must be capable of supporting at least 6 consecutive starts.

To ensure the utmost safety of everyone on board, each vessel must have two identical main air receivers as well as one emergency air bottle. This redundancy ensures that even in the event of a failure in one of the main air receivers, the engine can still be powered by the emergency air bottle, which can provide enough air to start the engine and bring the vessel to safety.

In summary, air reservoirs are a crucial component of any ship’s engine system and must be designed and tested to withstand the high-pressure demands of the engine. In order to ensure the safety of everyone on board, it is imperative that each vessel is equipped with the required number of air reservoirs as per Solas regulations.

Air Reservoir Mountings

When it comes to equipping air reservoirs, there are certain mountings that should be present to ensure safe and effective functioning. One of these essential mountings is the Fusible Plug. This plug is composed of Bismuth, Tin, and Lead in the ratio of 50%, 30%, and 20%, respectively, and has a melting point of 220 degrees Fahrenheit (104.4 degrees Celsius). It is typically fitted at the bottom of the reservoir or on the reservoir at the ship’s side when a relief valve is not directly fitted on the reservoir.

The primary function of the Fusible Plug is to release the compressed air in the event of abnormally high compressed air temperature. This is crucial to prevent any potential accidents or hazards that could arise from the overheating of the air reservoir. By melting at a specific temperature, the plug allows for the release of compressed air, which can prevent any damage or explosions.

Another important mounting that should be present in air reservoirs is the Atmospheric Relief Valve. This valve is provided as over-pressure protection and serves as a back-up for the Fusible Plug. In case of an Engine Room fire, when CO2 flooding is required, the valve must be opened before evacuating the engine room. This ensures that the compressed air is released and helps to prevent any damage or explosions that could occur during the CO2 flooding process.

It is worth noting that the air receiver relief valve opening could either open outside the engine room through the ship’s funnel or inside the engine room itself. In case of the latter, CO2 bottle calculations for fighting a fire in the Engine room are done accordingly, and the extra CO2 required is taken into consideration at the ship’s design stage. This demonstrates the importance of proper planning and design to ensure the safety and efficacy of the air reservoirs on board ships.

In summary, equipping air reservoirs with mountings such as the Fusible Plug and Atmospheric Relief Valve is essential for safe and effective functioning. These mountings work together to ensure that any potential hazards or accidents are prevented, and that the air reservoirs are able to operate as intended. Proper planning and design are also crucial to ensure the optimal performance of air reservoirs on ships.

In the world of maritime engineering, ensuring safety onboard is of utmost importance. As such, it’s important to understand the various components that make up a safe and secure vessel. One key component is the spring-loaded safety valve. This valve is responsible for regulating the pressure within the vessel and ensuring that it does not exceed a certain level. Specifically, a setting pressure of 32 bar (for a 30-bar working pressure) is recommended, with equal to or greater than 10% rise in accumulation of pressure that may be fitted directly or with extension. By utilizing a spring-loaded safety valve, the risk of pressure buildup and potential damage to the vessel is greatly reduced.

Another important component is the compensation ring. When a hole is cut or machined into a pressure vessel, the material around the hole is subjected to higher stresses. To reduce this stress and ensure structural integrity, a compensation ring is fitted. This ring acts as a flange on which a valve or fitting is usually mounted, and provides additional support to the vessel, thereby minimizing any potential risks.

In addition to the above, it’s also important to have both manual and automatic drain valves installed. These valves are responsible for draining any accumulated liquids from the vessel, and are an essential component in maintaining optimal conditions onboard.

Pressure gauges are also important, as they allow for easy monitoring and adjustment of the vessel’s pressure. By having access to accurate readings, engineers can quickly respond to any changes in pressure, ensuring the safety of everyone onboard.

Finally, access doors are crucial for providing easy entry and exit points within the vessel. They allow engineers to quickly and easily access important components for maintenance or repairs, and also provide an additional layer of safety in the event of an emergency.

Overall, by understanding and utilizing these components, engineers can ensure the safety and security of everyone onboard a vessel. It’s important to never overlook the importance of proper maintenance and adherence to safety protocols.

When it comes to the operation of air systems on ships, there are various valves and components that play important roles in ensuring the smooth functioning of the system. Among these, the main starting valve, auxiliary starting air valve, fitting valve, and service air or whistle air valve are crucial components that are commonly used on ships.

The main starting valve is a valve that is used to control the flow of compressed air to the main engine starting valve. The auxiliary starting air valve, on the other hand, is used to control the flow of compressed air to the auxiliary engines. Both of these valves are essential for starting the engines and ensuring their smooth operation.

In addition to these, there is also the fitting valve, which is used to connect the air system to various equipment and machinery on the ship. This valve is crucial for ensuring that the air system can be used to power different equipment and tools as required.

The service air or whistle air valve is yet another important component that is used to provide compressed air to various systems on the ship, including the whistle and other equipment that require compressed air to function properly.

When it comes to the construction of air systems on ships, the air receivers play a critical role. These are large cylindrical bottles that are used to store compressed air. In order to ensure that these receivers are able to withstand the high pressure of the compressed air, they are welded using full penetration welds. The welding details are carefully controlled to ensure that they meet the requirements of classification society regulations and are safe for use.

After the welding process is complete, the receivers are stress relieved or annealed at a high temperature of around 600 degrees Celsius. This helps to ensure that the metal is able to withstand the pressure of the compressed air without deforming or breaking.

To ensure that the air receivers are safe for use, they are subjected to periodic hydraulic testing. This involves testing the receiver at a pressure of 1.5 times the working pressure to ensure that it is able to withstand the pressure without rupturing or failing. For large receivers, this testing is required every 10 years to ensure that they remain safe and reliable for use on the ship.

Air Bottle Inspection

Air receivers are a critical component in any compressed air system, and as such, they must be carefully inspected and maintained to ensure optimal performance and longevity. One of the most significant issues that can arise with air receivers is corrosion, which can be caused by moisture accumulating within the vessel. Even with the proper operation of compressor cooler drains, a significant amount of moisture can collect, especially in humid conditions, leading to corrosion.

To prevent corrosion, it is essential to check air reservoir drains regularly to determine the amount of liquid present. In extreme conditions, drains may need to be used multiple times daily to remove accumulated emulsion. It is worth noting that corrosion is typically found near the air receiver drain.

Once a thorough visual inspection has been conducted, it may be necessary to measure the thickness of the air receiver using an ultra-sonic thickness gauge. If the thickness of the air receiver is found to be compromised, it is crucial to reduce the air pressure contained in that particular air bottle. This can be done by changing the cut-in and cut-off settings of the air compressor, as well as adjusting relief valve settings when that particular receiver is in use. Additionally, the air receiver can be isolated entirely and kept on standby, allowing it to be filled manually with caution whenever required.

All internal welds and any small changes in cross-section must be thoroughly inspected to ensure that the air receiver is functioning correctly. If the air bottle is too small to be manually entered, an internal inspection can be carried out using a camera with a probe.

To further protect against corrosion, it is recommended that the internal surface of the air receiver be coated with a suitable material. Graphite suspension in water, Linseed oil, Copal Vanish or Epoxy coating are all excellent choices, providing basic properties such as anti-corrosion, anti-toxic, and anti-oxidation.

In conclusion, regular inspection and maintenance of air receivers is essential to ensure that they continue to operate at optimal performance levels. By identifying and addressing any potential issues early on, it is possible to extend the lifespan of these critical components and avoid costly downtime due to unexpected failures.

Safety Devices On Main Air Bottle

The marine industry has always been subject to constant innovation and development, particularly in terms of safety and reliability. This is particularly true in relation to the control air system of marine vessels. The control air system is an essential component of the vessel that controls the pneumatic equipment on board. The control air system comprises of various components such as fusible plug, pressure relief valve, atmospheric relief valve, low-pressure alarm, and automatic or remote-control moisture drain valve.

The fusible plug is a critical safety device that prevents the pressure inside the vessel from reaching a critical point, which could lead to an explosion. The pressure relief valve is another vital component that is designed to protect the control air system against overpressure. It operates by opening when the pressure inside the control air system exceeds a predetermined level, allowing the excess air to escape.

Similarly, the atmospheric relief valve is another important safety device that is designed to protect the control air system from vacuum conditions. The atmospheric relief valve opens when there is a vacuum condition inside the system, allowing air to enter and equalize the pressure.

To ensure the trouble-free operation of the control-air systems, low-pressure alarms are used to alert the engine crew if the pressure drops below a predetermined level. The automatic or remote-control moisture drain valve is another vital component of the control air system. It is designed to remove moisture from the compressed air and prevent contamination that can cause malfunctioning of the control equipment and valves.

Since control air equipment is sensitive to contaminants, it is essential to ensure that the compressed air supplied is clean and dry. The presence of water, oil, or other contaminants in the compressed air can cause moving parts in control equipment and valves to stick, leading to general deterioration of diaphragms, spools, and other parts made of rubber. Additionally, contaminants in the compressed air can cause rust build-up, metallic wear, and other small particles that can cause damage by abrasion.

To prevent the presence of contaminants in the compressed air, special provisions must be made to ensure that the air quality is high. This is particularly important when the source of control and instrument air is the main air compressors and the main air reservoir itself. The pressure reducing valve, which reduces the main air pressure to the 7 or 8 bar required by the control air system, can be affected by emulsion carry-over and may require frequent cleaning to prevent air contamination.

Although automatic drain traps can be fitted in the control air system, many traps require daily draining by the engine crew. Therefore, it is crucial to ensure that the engine crew is adequately trained to identify and rectify any issues with the control air system to ensure the safe and efficient operation of the vessel. In conclusion, the control air system is a vital component of marine vessels that must be maintained to ensure safe and reliable operation.

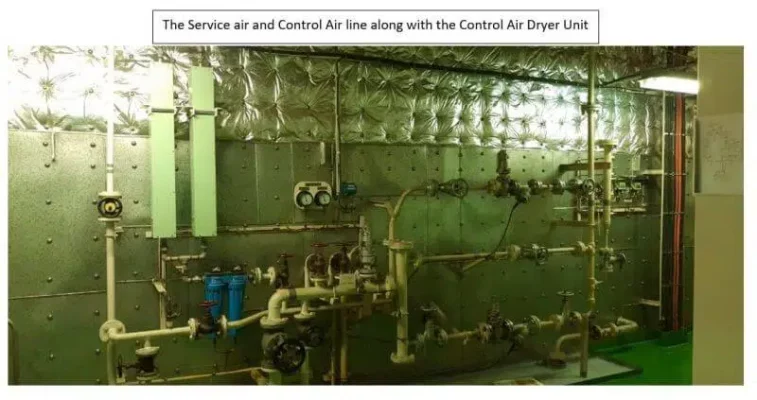

Controlling air quality on a vessel is a crucial part of ensuring efficient and safe operation. Large amounts of free moisture and oil emulsion carry-over in the air can cause a number of issues including decreased efficiency of machinery and corrosion of equipment. Fortunately, these issues can be addressed with the use of special control-air membrane filters installed in the control air line.

A typical control air filter arrangement includes an oil and moisture collecting filter followed by a membrane air dryer filter. This treatment of air through these membrane filters results in the air being filtered and dried to remove virtually all traces of oil, moisture, and air impurities. A simple line air filter is provided with a small plastic float and auto-drain arrangement, and it can also be drained manually if the vessel enters a highly humid environment and frequent draining is required.

The filter dryer unit is made up of a primary filter, secondary filter, and membrane hollow fiber elements. The control air enters the dryer chamber through the line filter located in the lower part of the dryer unit. In the dryer unit, the primary filter removes the coarse rust particles, dust, and other larger impurities, while the secondary filter acts like a coalescer, separating water droplets and oil mists up to 0.3 microns. A differential pressure gauge indicates the condition of the primary and secondary filters, and a higher differential pressure indicates a dirty membrane filter. The membrane elements are to be renewed as per the ship’s PMS.

It is also important to consider the high-pressure air piping from the air compressor to the receiver. The piping should be as smooth as possible without any bends in the pipeline so as to allow air to flow freely to the receiver without restrictions. Bends in the piping can create backpressure in the line in case of accumulated moisture or oil emulsion in the line.

Overall, proper control air filtration is essential to maintain equipment efficiency and avoid costly repairs. By utilizing these special control-air membrane filters and ensuring smooth high-pressure air piping, vessels can operate at their maximum potential while also maintaining safe and efficient operations.

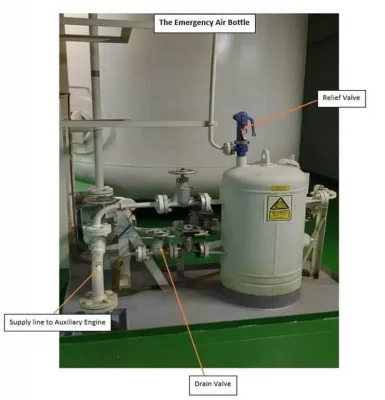

Emergency Air Compressor And Emergency Air Bottle

The importance of having a reliable emergency air compressor on board cannot be overstated. This compact and versatile piece of equipment can be powered by an independent prime mover, such as an engine, or draw power from the emergency switchboard. Its primary function is to fill up the emergency air bottle with a sufficient volume of air, which can then be used to start the auxiliary engine of a dead ship.

The emergency air compressor also plays a critical role in the operation of the Emergency Shut-Off Valve system, where control air is necessary. Moreover, an emergency QCV air bottle with 7 bar air pressure is used to operate all Quick Closing valves, fire and funnel dampers on board. This arrangement typically comprises a 7 bar Emergency QCV air bottle with QCV- shut off valves that are always ready to be used in the event of an emergency.

In case of an uncontrollable fire in the engine room, the Quick Closing valves are activated, which supplies control air to SHUT specific outlet valves of all Fuel Oil and Lube Oil tanks and ER funnel and Blower dampers, thereby cutting off all fuel and air supply. This effectively helps to prevent the spread of fire and contain the damage.

It is worth noting that control air supply is also essential in Emergency Shut Down Systems (ESDS) on Gas Tankers. In such scenarios, a reliable and efficient emergency air compressor is indispensable.

In conclusion, the importance of having an emergency air compressor on board cannot be overemphasized. It is a crucial piece of equipment that plays a vital role in ensuring the safety of the ship and crew. However, it is essential to ensure that the emergency air compressor is regularly maintained and checked to ensure its optimal performance. Finally, it is important to note that the author’s views expressed in this article do not necessarily reflect the views of Marine Insight, and all data and charts used have been sourced from available information and have not been authenticated by any statutory authority.

FAQ

- What is the purpose of compressed air lines on ships?

- How do compressed air lines work on a ship?

- What types of equipment on a ship rely on compressed air lines?

- How are compressed air lines maintained on a ship?

- What safety precautions are necessary when working with compressed air lines on a ship?

- How can compressed air line failures be prevented on a ship?

- What are the common issues faced with compressed air lines on a ship and how can they be resolved?

- What regulations apply to the installation and maintenance of compressed air lines on ships?

- What are the best practices for operating and maintaining compressed air lines on a ship?

- How can compressed air lines impact the performance and efficiency of a ship’s equipment and systems?

What is the purpose of compressed air lines on ships?

Compressed air lines play a crucial role in the operation and safety of ships. In this article, we will explore the purpose of compressed air lines on ships, their function, and their maintenance requirements.

The primary purpose of compressed air lines on ships is to provide a reliable source of compressed air that is used to power various shipboard systems and equipment. These systems include but are not limited to the starting air system, control air system, emergency air system, and pneumatic control systems.

The starting air system, for example, is used to start the ship’s main engine and auxiliary engines. This system typically consists of an air compressor, air storage tanks, and a network of air pipes and valves. When the engine is started, the compressed air is released from the storage tanks and used to rotate the engine’s starter motor. The starter motor, in turn, cranks the engine until it reaches its operating speed.

Another important use of compressed air on ships is in the control air system. This system is used to control various valves and dampers on board the ship, which regulate the flow of fluids and gases. For example, the control air system is used to operate quick-closing valves, which are used to isolate a section of the ship in the event of an emergency. The control air system is also used to operate fuel oil and lubricating oil outlet valves, as well as the ship’s funnel dampers and blower dampers.

In addition to the starting air and control air systems, ships also have an emergency air system, which provides a source of compressed air in the event of an emergency. This system is typically powered by a separate air compressor, and the compressed air is stored in an emergency air bottle. The emergency air system is used to power emergency equipment, such as the emergency generator and emergency fire pumps.

Given the critical role that compressed air lines play in the safe operation of ships, it is essential to ensure that they are properly maintained. This includes regular inspections and testing of the compressed air lines and associated equipment, as well as routine maintenance of the air compressors and air storage tanks. Regular maintenance helps to prevent compressed air line failures and ensures that the systems operate as designed in the event of an emergency.

In conclusion, compressed air lines are an essential component of shipboard systems and equipment. They play a critical role in the safe and efficient operation of the ship and must be properly maintained to ensure their reliability. As such, it is essential that ship owners and operators prioritize the proper maintenance and upkeep of their compressed air lines and associated equipment.

How do compressed air lines work on a ship?

Compressed air lines are an essential component of the ship’s systems, and their proper operation is critical to the safe and efficient operation of the vessel. In this article, we will explore how compressed air lines work on a ship, their components, and their maintenance requirements.

Compressed air lines on ships work by supplying compressed air to various shipboard systems and equipment. The compressed air is typically generated by an air compressor, which draws in air from the surrounding environment and compresses it to a higher pressure. The compressed air is then stored in air storage tanks, which are typically located in the engine room.

One of the primary uses of compressed air on a ship is in the starting air system. This system is used to start the ship’s main engine and auxiliary engines. The starting air system typically consists of an air compressor, air storage tanks, and a network of air pipes and valves. When the engine is started, the compressed air is released from the storage tanks and used to rotate the engine’s starter motor. The starter motor, in turn, cranks the engine until it reaches its operating speed.

Compressed air is also used in the control air system, which is used to control various valves and dampers on board the ship. The control air system is used to operate quick-closing valves, which are used to isolate a section of the ship in the event of an emergency. The control air system is also used to operate fuel oil and lubricating oil outlet valves, as well as the ship’s funnel dampers and blower dampers.

In addition to the starting air and control air systems, ships also have an emergency air system, which provides a source of compressed air in the event of an emergency. This system is typically powered by a separate air compressor, and the compressed air is stored in an emergency air bottle. The emergency air system is used to power emergency equipment, such as the emergency generator and emergency fire pumps.

The components of compressed air lines on a ship include the air compressor, air storage tanks, air pipes and valves, and pressure regulators. The air compressor is the component that generates the compressed air, while the air storage tanks are used to store the compressed air. The air pipes and valves are used to transport the compressed air to the various shipboard systems and equipment, while the pressure regulators are used to control the pressure of the compressed air.

Given the critical role that compressed air lines play in the safe operation of ships, it is essential to ensure that they are properly maintained. This includes regular inspections and testing of the compressed air lines and associated equipment, as well as routine maintenance of the air compressors and air storage tanks. Regular maintenance helps to prevent compressed air line failures and ensures that the systems operate as designed in the event of an emergency.

In conclusion, compressed air lines are a vital component of shipboard systems and equipment. They play a critical role in the safe and efficient operation of the ship and must be properly maintained to ensure their reliability. As such, ship owners and operators must prioritize the proper maintenance and upkeep of their compressed air lines and associated equipment to ensure the safe operation of the vessel.

What types of equipment on a ship rely on compressed air lines?

Compressed air lines play a crucial role in the functioning of various equipment on board a ship. From starting an auxiliary engine to operating quick-closing valves, compressed air lines are essential to keep the ship’s systems running smoothly. In this article, we will explore the different types of equipment on a ship that rely on compressed air lines.

- Starting an Auxiliary Engine One of the primary uses of compressed air on a ship is to start the auxiliary engine. The compressed air is stored in an air bottle, and when released, it turns the engine over, helping it to start.

- Operating Quick-Closing Valves (QCV) Quick-closing valves are installed on board ships to prevent flooding or fire in case of an emergency. The compressed air is used to operate the QCVs, which can shut off the flow of liquids or gases quickly.

- Emergency Shut-Off Valve Operating System The emergency shut-off valve operating system is another crucial component that relies on compressed air. This system is designed to cut off the flow of fluids in case of an emergency. The compressed air is used to operate the shut-off valves quickly.

- Funnel and Blower Dampers The dampers on a ship are used to regulate the flow of air and gases. Compressed air is used to operate the dampers, which can quickly close in case of an emergency.

- Pneumatic Tools Compressed air is also used to power various pneumatic tools on board ships. These tools include drills, grinders, impact wrenches, and many more.

- Hydraulic Power Packs Hydraulic power packs are used to operate various machinery on board ships. They rely on compressed air to build pressure and provide the force needed to operate the hydraulic system.

- Deck Machinery Many of the deck machinery on board ships, such as winches and cranes, use compressed air to operate. This compressed air provides the power needed to lift heavy loads and move equipment around the ship.

- Steering Gear System The steering gear system on a ship is used to control the direction of the vessel. Compressed air is used to operate the hydraulic system that controls the rudder, allowing the ship to turn and maneuver.

- Marine Incinerators Marine incinerators are used to burn waste generated on board ships. They rely on compressed air to operate the burners, which provide the heat needed to burn the waste.

- Cargo Hold Ventilation Cargo holds on board ships need to be properly ventilated to prevent damage to the cargo. Compressed air is used to power the ventilation system, which circulates air and removes moisture from the cargo holds.

In conclusion, compressed air lines are essential to the functioning of various equipment on board a ship. From starting engines to operating valves and tools, compressed air plays a vital role in keeping the ship’s systems running smoothly. It is crucial to maintain and repair these systems regularly to ensure they function correctly and avoid any potential accidents or breakdowns.

How can compressed air line failures be prevented on a ship?

Compressed air lines are an essential component of the machinery system on board ships. These lines are responsible for providing control air supply to various equipment and systems, such as the engine room machinery, control systems, and safety equipment, among others. Given the importance of compressed air lines, it is crucial to ensure their proper functioning and prevent any failures that can result in significant safety hazards and operational disruptions.

In this article, we will discuss various measures that can be taken to prevent compressed air line failures on ships.

Regular maintenance and inspection

Regular maintenance and inspection are essential to ensure the proper functioning of compressed air lines. This includes checking for any leaks, damage, or wear and tear on the lines, fittings, valves, and other components. It is also crucial to ensure that the air compressors are functioning correctly and that the air quality is maintained as per the requirements.

Training and awareness

Training and awareness among the crew members are crucial to prevent compressed air line failures. The crew must be familiar with the functioning of the compressed air lines and the safety measures to be taken in case of any failure. They should be trained on the proper handling and maintenance of the lines and equipment to prevent any damage or accidents.

Use of quality materials

The use of quality materials for the construction and maintenance of compressed air lines is crucial to prevent any failures. The lines, fittings, and valves must be made of corrosion-resistant materials that can withstand the harsh marine environment. The use of substandard materials can lead to premature failure and damage to the equipment and machinery.

Proper installation and alignment

Proper installation and alignment of the compressed air lines are crucial to prevent any failures. The lines must be installed as per the manufacturer’s instructions and aligned correctly to prevent any stress or damage to the lines and fittings. The lines must be adequately supported to prevent any sagging or bending, which can lead to damage and failure.

Regular testing and monitoring

Regular testing and monitoring of the compressed air lines are crucial to prevent any failures. This includes testing the lines for pressure, leaks, and air quality. The testing must be carried out as per the regulations and standards, and any deviations must be addressed immediately. The lines must be monitored regularly for any signs of damage or wear and tear, and any corrective measures must be taken promptly.

In conclusion, compressed air lines are critical components of the machinery system on board ships, and any failures can result in significant safety hazards and operational disruptions. Therefore, it is crucial to ensure their proper functioning and prevent any failures. This can be achieved by regular maintenance and inspection, training and awareness, use of quality materials, proper installation and alignment, and regular testing and monitoring. By following these measures, we can ensure the safe and reliable operation of compressed air lines on ships.

What are the common issues faced with compressed air lines on a ship and how can they be resolved?

Compressed air lines are crucial for various systems on board ships. However, like any other machinery, these lines are also prone to issues and failures that can impact the operations of the ship. In this article, we will discuss some of the common issues faced with compressed air lines on a ship and how they can be resolved.

- Leaks: One of the most common issues with compressed air lines is leaks. Leaks can occur due to various reasons such as loose fittings, damaged hoses, or faulty valves. If not addressed promptly, leaks can result in a loss of pressure, reduced efficiency, and even system failure.

Solution: To prevent leaks, regular inspection and maintenance of the compressed air system are essential. A proper inspection schedule must be in place, and any leaks must be addressed promptly. This includes replacing damaged hoses, tightening fittings, and replacing faulty valves.

- Contamination: Another common issue faced with compressed air lines is contamination. Contaminants such as dirt, water, or oil can enter the system and cause damage to the machinery, leading to reduced efficiency and even system failure.

Solution: To prevent contamination, it is essential to have a proper filtration system in place. The filters must be regularly checked and replaced as required. Additionally, the air receiver tank must be drained regularly to remove any moisture that may have accumulated.

- Corrosion: Corrosion is another significant issue that can affect compressed air lines. Corrosion can occur due to exposure to seawater or moisture, and it can cause damage to the pipes and valves.

Solution: To prevent corrosion, it is essential to use materials that are resistant to corrosion, such as stainless steel. Additionally, regular inspection and maintenance of the compressed air system must be carried out to detect and address any signs of corrosion promptly.

- Inadequate pressure: Inadequate pressure is another common issue faced with compressed air lines. Inadequate pressure can result in reduced efficiency and even system failure.

Solution: To prevent inadequate pressure, regular inspection and maintenance of the system are essential. This includes checking the pressure gauges, replacing damaged hoses, and ensuring that the system is operating at the required pressure.

- Overpressure: Overpressure can occur when the pressure in the compressed air system exceeds the recommended levels. Overpressure can result in damage to the machinery and even system failure.

Solution: To prevent overpressure, it is essential to have a proper pressure relief valve in place. The valve must be regularly checked and replaced as required.

In conclusion, compressed air lines are critical for various systems on board ships. Therefore, it is essential to have a proper inspection and maintenance schedule in place to detect and address any issues promptly. Regular inspection, maintenance, and replacement of damaged components can help prevent failures and ensure the efficient operation of the compressed air system.

What regulations apply to the installation and maintenance of compressed air lines on ships?

Compressed air lines are a vital component of a ship’s machinery, and as such, their installation and maintenance are subject to strict regulations. These regulations aim to ensure the safety of the ship and its crew, as well as the protection of the environment.

The International Maritime Organization (IMO) sets out guidelines and regulations for the installation and maintenance of compressed air systems on ships. These guidelines are based on the International Convention for the Safety of Life at Sea (SOLAS), which sets out the minimum safety requirements for ships.

According to SOLAS regulations, compressed air systems must be designed, constructed, and installed in a manner that ensures the safety of the crew and the vessel. The regulations require that all compressed air systems be installed and maintained in accordance with the manufacturer’s instructions and that all systems must be inspected and tested at regular intervals.

In addition to SOLAS regulations, many countries have their own regulations and requirements for the installation and maintenance of compressed air systems on ships. These regulations may include specific requirements for the materials and components used in the system, as well as the testing and inspection procedures that must be followed.

One of the key regulations that apply to the installation and maintenance of compressed air systems on ships is the Pressure Vessel Inspection Code (PVIC). The PVIC provides guidelines for the design, construction, and inspection of pressure vessels, including compressed air systems.

The PVIC requires that all pressure vessels, including compressed air systems, be inspected and tested at regular intervals to ensure that they are in safe working order. The inspections must be carried out by a qualified inspector, and the results of the inspections must be recorded and retained for future reference.

Another regulation that applies to compressed air systems on ships is the International Safety Management Code (ISM). The ISM Code requires that all ships have a safety management system in place that includes procedures for the safe operation and maintenance of all machinery and equipment, including compressed air systems.

Under the ISM Code, ship operators are required to carry out regular safety audits to ensure that their safety management systems are effective and that all equipment is being maintained and operated safely.

To comply with these regulations, ship operators must ensure that their compressed air systems are installed and maintained by qualified personnel who have the necessary training and experience. They must also ensure that all components and materials used in the system meet the required standards and that the system is regularly inspected and tested to ensure its safe operation.

In conclusion, the installation and maintenance of compressed air systems on ships are subject to strict regulations and guidelines to ensure the safety of the ship and its crew. It is essential that ship operators comply with these regulations and work with qualified personnel to install and maintain their compressed air systems to the required standards.

What are the best practices for operating and maintaining compressed air lines on a ship?

Compressed air lines are a crucial part of the machinery and equipment on board a ship. They are used to power various systems such as valves, actuators, and control systems. Proper operation and maintenance of compressed air lines are essential for the safe and efficient functioning of a ship. In this article, we will discuss the best practices for operating and maintaining compressed air lines on a ship.

- Regular inspection and maintenance Regular inspection and maintenance are critical to ensuring the smooth operation of compressed air lines. The air lines, filters, regulators, and other components should be inspected regularly for any signs of wear and tear. Any defects or damage should be repaired or replaced immediately.

- Follow the manufacturer’s instructions The manufacturer’s instructions for operation and maintenance should always be followed. This includes the recommended pressure levels, cleaning procedures, and lubrication requirements. Failure to follow the manufacturer’s instructions can lead to premature failure of the compressed air lines.

- Proper installation Proper installation of compressed air lines is crucial for their safe and efficient operation. The lines should be properly secured and supported to prevent excessive vibration or movement. The installation should also include the use of proper fittings, connectors, and hoses.

- Regular testing Regular testing of compressed air lines is essential to ensure their safe operation. Pressure tests should be conducted regularly to check for leaks and proper pressure levels. The testing should be conducted using the appropriate equipment and following the correct procedures.

- Cleanliness Compressed air lines should be kept clean and free from debris. Dust and debris can cause blockages and damage to the system. Regular cleaning and inspection of filters and other components are essential to ensure the system’s cleanliness.

- Training and education Proper training and education of crew members are crucial to ensuring the safe and efficient operation of compressed air lines. Crew members should be trained in the proper use and maintenance of the system. They should also be familiar with the safety procedures in case of an emergency.

- Record keeping Proper record keeping is crucial for the efficient operation and maintenance of compressed air lines. Records should be kept of all inspections, maintenance, repairs, and testing conducted on the system. This information is essential for tracking the system’s performance and identifying any issues that may arise.

In conclusion, compressed air lines are a critical component of a ship’s machinery and equipment. Proper operation and maintenance are essential to ensure their safe and efficient functioning. Following the best practices for operating and maintaining compressed air lines on a ship can help to prevent system failures, reduce downtime, and ensure the safety of the crew and vessel.

How can compressed air lines impact the performance and efficiency of a ship’s equipment and systems?

Compressed air lines are a critical component in ensuring the smooth operation and functionality of a ship’s equipment and systems. When maintained properly, compressed air lines provide a reliable and efficient source of power for various machinery and control systems. However, issues with compressed air lines can have a significant impact on a ship’s performance and efficiency. In this article, we will discuss the effects of compressed air line issues on a ship’s equipment and systems, as well as the steps that can be taken to mitigate them.

One of the most common issues with compressed air lines is leakage. When air leaks from the system, it can reduce the air pressure, causing a decrease in performance and efficiency. Additionally, leakage can lead to wasted energy and increased fuel consumption. Regular inspection and maintenance of compressed air lines can help identify and repair leaks before they become significant issues.

Another issue that can impact the performance of compressed air lines is contamination. Moisture, oil, and other particulate matter can accumulate in the air lines, affecting the quality of the compressed air. This can cause issues with equipment and systems that rely on the compressed air for their operation. To mitigate this, proper filtration and maintenance of air lines are essential.

Compressed air lines can also have an impact on the efficiency of a ship’s control systems. For example, emergency air compressors play a critical role in starting auxiliary engines and shutting off valves in the event of a fire or other emergency. If these systems are not functioning correctly due to issues with the compressed air lines, it can lead to delays and potentially dangerous situations. Routine inspection and testing of these systems can help ensure they are functioning correctly.

In addition to regular maintenance and inspection, there are several best practices for operating and maintaining compressed air lines on a ship. For example, it is important to ensure that the air compressor is appropriately sized and capable of meeting the demands of the equipment and systems it serves. Proper filtration and drying of the compressed air can also help to reduce the risk of contamination and extend the life of the equipment.

Finally, it is essential to ensure that all regulations and guidelines are followed when installing and maintaining compressed air lines on a ship. The International Maritime Organization (IMO) has established guidelines for the installation and maintenance of compressed air systems, and compliance with these guidelines is critical to ensure the safety and reliability of the equipment and systems on board.

In conclusion, compressed air lines play a vital role in the operation and efficiency of a ship’s equipment and systems. Issues with compressed air lines can have a significant impact on performance, efficiency, and safety. Regular maintenance and inspection, proper filtration and drying, and compliance with regulations and guidelines are essential for ensuring the proper operation and reliability of compressed air lines on a ship. By following these best practices, ship operators can ensure the smooth and efficient operation of their vessels.

Disclaimer

Shipping and Delivery Information

We understand the excitement and anticipation that comes with every purchase. That’s why we’ve established a clear and detailed shipping and delivery process to ensure that you are fully informed every step of the way, from the moment you finalize your order to when it arrives at your doorstep. This information is designed to meet and exceed merchant rules, offering you peace of mind and clarity on what to expect regarding the shipping and receiving of your goods.

Order Processing:

- Initial Confirmation: Once your order is placed, you will receive an immediate email confirmation. This email serves as an acknowledgment of your order and provides you with a unique order number for future reference.

- Packing Period: Our dedicated warehouse team takes great care in preparing your order. Please allow us 2 working days to carefully package your items. This time frame ensures that your products are securely packed, properly labeled, and prepared for shipment, minimizing the risk of damage during transit. Each product is inspected to ensure it meets our high-quality standards before being packaged.

Shipping:

- Carrier Handoff: After the packing period, your parcel is handed over to our trusted shipping carrier. This transition marks the beginning of the shipping phase.

- Shipping Time Frame: Our standard shipping timeframe is 5 to 7 working days. This period begins once the carrier has received your package from our warehouse. The delivery times are estimates based on the carrier’s guidelines and the destination of the package. It’s important to note that these are working days, excluding weekends and public holidays.

- Tracking and Updates: Upon dispatch, you will receive a tracking number via email. This number allows you to monitor the journey of your package in real-time. We also partner with our carriers to provide regular updates via email or SMS, ensuring you are informed of any progress or changes in the delivery schedule.

Delivery:

- Final Mile: The final leg of your package’s journey is known as the “final mile.” During this stage, local postal services or last-mile delivery partners take over to ensure your package reaches its final destination safely and efficiently.

- Receiving Your Package: Upon arrival, you might be required to sign for the delivery, depending on the carrier’s policy and the nature of the goods. If you are not available to receive the package in person, the carrier will leave a notice with further instructions on how to arrange for a redelivery or pickup from a local post office or depot.

- Customer Support: Should you have any questions or concerns about your delivery, our customer support team is here to assist. From tracking assistance to addressing delivery queries, we’re committed to ensuring your shopping experience is seamless and satisfactory.

We pride ourselves on transparency and communication throughout the shipping and delivery process. Our goal is to provide you with a smooth, hassle-free experience, keeping you informed and satisfied from the moment you shop with us to the excitement of unboxing your purchase.

LEGAL DISCLAIMER: PRODUCTS INTENDED EXCLUSIVELY FOR SPORTING AND COMPETITIVE USE

Important: Before proceeding with the purchase or use of our sport exhausts, please read the following notice carefully.

The products sold through this website are intended exclusively for sporting and competitive use. This means they have been designed and manufactured to be used in controlled environments, such as closed circuits or areas designated for sporting competitions, where emission and noise regulations may differ from those applied on public roads.

Public Road Use Not Allowed: It is emphasized that the installation and use of these devices on vehicles intended for circulation on public roads may not be permitted under the laws of your reference country regarding emission and noise regulation, as they are not designed for road use but for sporting use.

Buyer’s Responsibility: It is the buyer’s responsibility to ensure that the use of the purchased products complies with all applicable laws and regulations. The buyer assumes all legal liabilities for any non-compliant use of the products, including the installation and operation of such devices on unauthorized vehicles or in ways that violate applicable laws.

By continuing with the purchase, the buyer acknowledges and agrees that the use of the products is limited to sporting and competitive contexts as defined above and assumes full responsibility for any legal consequences arising from improper use of the products.

A Comprehensive Guide to Compressed Air Lines on Ships: Everything You Need to Know

Compatibility:

It is the responsibility of the customer to ensure that the product is compatible with their vehicle. We recommend consulting with a professional mechanic before purchasing to confirm compatibility. BOATxt is not responsible for any issues that may arise from the use of our products, including but not limited to damage to the vehicle or personal injury.

Warranty:

All of our products come with a 2-year warranty in accordance with international standards. If you experience any issues with your product within the warranty period, please contact us for assistance. The warranty does not cover damages caused by improper installation, misuse, or external factors such as accidents or natural disasters.

Return Policy

We are committed to ensuring our customers’ complete satisfaction. If you are not completely satisfied with your purchase made on our website, you have the right to return the goods or all products purchased directly from our site within 14 days of receiving them. To be eligible for a return, items must be returned in their original packaging, with labels and protective seals intact, and in the same condition as when they were received. Products purchased directly from our website must be returned to our warehouse to obtain a full refund; please note that shipping costs for returning the goods may be the responsibility of the user. BOATxt is not responsible for any items lost during the return shipping.

Return Procedure:

- Send a request via email to info@boatxt.com within the return period.

- In the email, specify “Return” as the subject and provide a reason for the return.

- You will receive a response with instructions on how to proceed with the return.

- Follow the instructions to create your return label.

- Ship the order via courier to : .

- ⚫️Address: Creative Tower – Hamad Bin Abdulla Road – Office 4201 – Fujairah – U.A.E. –

- ⚫️WHATSAPP➡️ + 1 (213) 789-7175

- ⚫️E-MAIL ➡️ info@Boatxt.com

payment refund times

Once we receive the returned goods, we will take 2 working days to issue a refund on the card used for the purchase. The customer will receive a 100% refund of the amount spent, excluding shipping costs for returning the goods.

We thank you for your patience and understanding.

Terms and Conditions

This website provides only the product with well-indicated codes and specifications. Please rely on an experienced workshop for the installation and choice of the product. We do not assume any responsibility for errors in choice, installation, or programming of the devices.

*The price is intended for a single product

*Days are always working days

All guides on this website are for illustrative purposes only. For many products, the use of special tools may be necessary. We always recommend seeking the advice of a specialized repair center for the selection and installation or programming of products purchased anywhere. We do not assume any responsibility for damage to property or persons, or user errors in the application of a guide on this website or for any other occurrence.

Product is not original but fully interchangeable with it

All rights reserved. All trade names and logos are registered trademarks of the respective manufacturers indicated

The trademarks mentioned on this site are the exclusive property of the automotive companies and are used here exclusively to facilitate the search for vehicles by our customers. We do not assume any responsibility for damages to property or persons, or user errors in the application of a guide on this website or for any other occurrence.

Secure Payments

When making purchases on our website, you can be confident that your transaction is secure. All financial transactions are processed on the secure and certified servers of PayPal or Stripe. These platforms allow us to accept payments from all VISA, VISA ELECTRON, MAESTRO, POSTEPAY, AMERICAN EXPRESS, AURA, and DISCOVER credit cards.

Quality Guarantee

Choose safety, savings, and professionalism by choosing us. We offer top-level customer support that will never leave you alone during the pre- and post-purchase phases. We offer top-quality products and intelligent, secure savings. Don’t trust inexperienced sellers.

NOTE: In the event that the product is not available in stock, we reserve the right to issue a full and immediate refund.